Why Choose DSI – Premium Spiral Implant Line

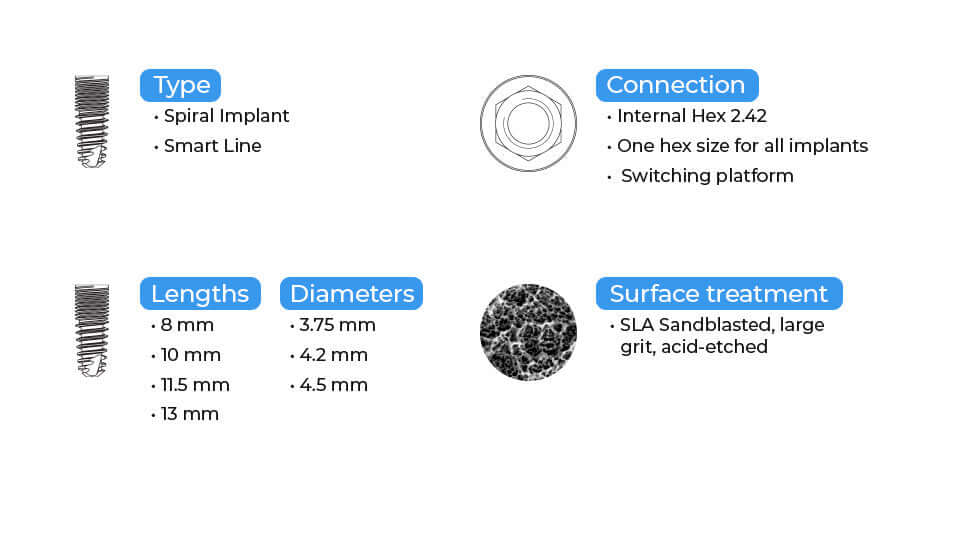

DSI is a young and fast-growing European brand offering a breakthrough combination of compatibility, precision, and price-performance value. The Premium Spiral Implant Line is designed for European dentists who value restorative flexibility, cross-platform compatibility, and seamless digital integration.

- ✔ Market-leading prosthetic range (angled, multi-unit, overdenture, CAD/CAM-ready)

- ✔ STL, guided surgery, scan bodies, and digital lab integration

- ✔ Ideal for immediate loading, soft bone, and full-arch restorations

- ✔ Compatible with Zimmer®️, Alpha-Bio, MIS, AB Dental, Noris (2.42 mm internal hex)

- ✔ Competitive pricing: €50–€75

Comparative Table: DSI vs. Leading Implant Brands

| Brand (Line) | Price (€) | Advantages | Disadvantages |

|---|---|---|---|

| DSI (Premium Spiral Line) | 50–75 | Widest prosthetic range; Cross-platform compatibility; Fully digital | Young but rapidly growing in Europe |

| AB Dental (MPI) | 120–140 | Deep thread design; Guided kits; Digital support | Proprietary components; Higher price |

| Alpha-Bio Tec (SPI) | 100–120 | Easy to use; Strong distribution; Reliable | Closed system; Less digital support |

| Noris Medical (Tuff) | 130–150 | Advanced surgical solutions; Zygomatic; Internal hex | Higher cost; Less mainstream |

| MIS (SEVEN) | 150–200 | EU trusted; Aesthetic excellence; Digital-ready | Pricey; Closed system |

| JDentalCare (JDEvolution) | 110–130 | Universal prosthetic connection; Simplified workflow | Limited academic exposure |

| Zimmer Biomet (TSV) | 200–250 | Highly documented; Global academic standard | Expensive; Proprietary |

| BEGO (Semados RI-Line) | 120–150 | German precision; Reliable in general practice | Limited visibility outside DACH |

| Anthogyr (Axiom REG) | 150–180 | Straumann integrated; CAD/CAM optimized | Incompatible with Zimmer-style components |

| Sweden & Martina (HTA) | 110–140 | Strong soft-tissue outcomes; Italian innovation | Regionally focused |

| BTI (Interna®️) | 130–160 | Biological healing system (PRGF); Tissue integration | Proprietary ecosystem |

| Medentika (MT Line) | 90–120 | Highly cost-effective; Broad prosthetic compatibility | Limited implant range |

Frequently Asked Questions (FAQ)

Question: Is DSI compatible with Alpha-Bio, MIS, AB Dental, and Noris implants?

Answer: Yes. All use the 2.42 mm internal hex platform for full prosthetic compatibility.

Question: What makes DSI a better choice?

Answer: DSI offers the widest prosthetic catalog, full digital integration, and unmatched value.

Question: Can DSI implants be used for immediate loading or full-arch cases?

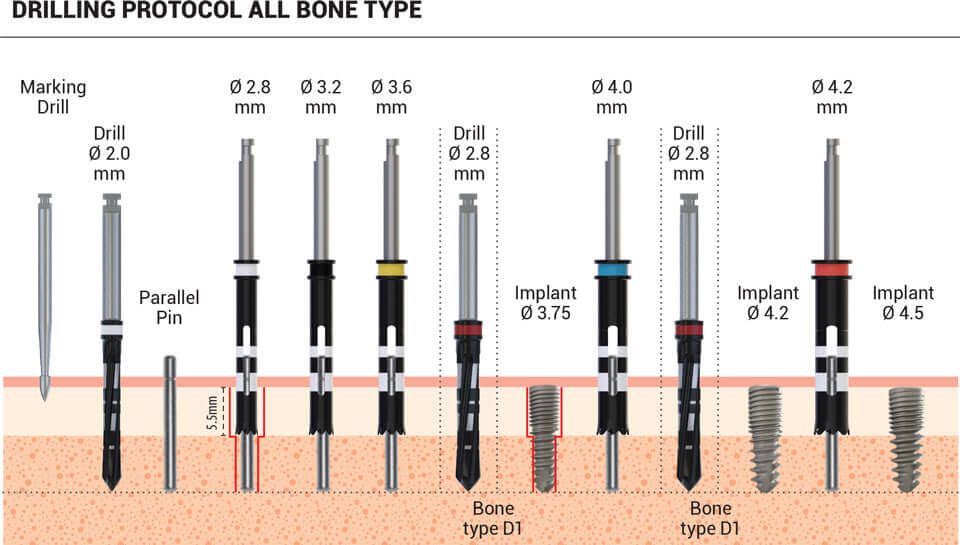

Answer: Absolutely. The Premium Spiral implant provides excellent primary stability even in soft bone.

Question: Does DSI support digital workflows?

Answer: Yes – from STL files to scan bodies and surgical guides, DSI is fully digital-ready.